Softening Measurement of Coated Steel

Introduction

We measured coated steel shrinkage using TMA.

Instrument

TMA adopts the Rigaku’s establishment reputation on differential expansion principle where the thermal expansion or shrinkage generated from the detection mechanism itself can be cancelled. It offers high accuracy and excellent reproducibility in expansion and shrinkage measurements, even with low expansion materials or thin materials.

Measurement and analysis

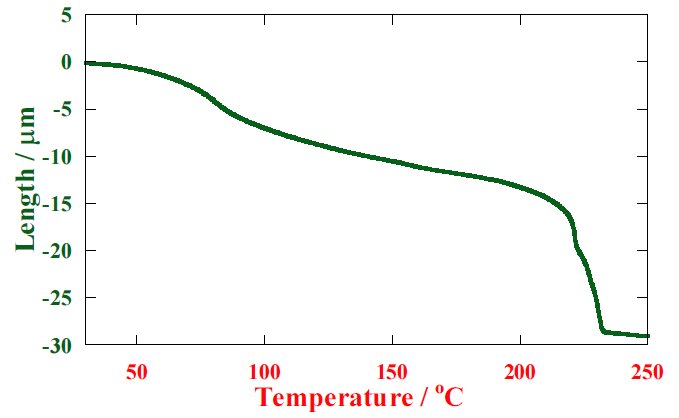

Figure 1: TMA measurement result for coated steel.

Figure 1 shows the high-sensitivity differential penetration measurement result of coated steel. There are two changes in shrinkage, low-temperature side and high-temperature side mainly.

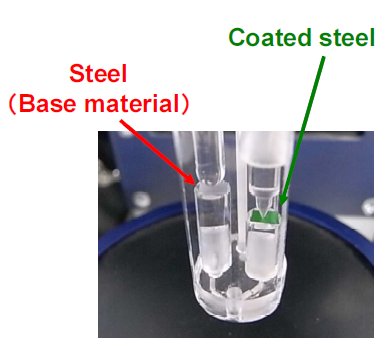

Although the material is mainly made of steel so the thermal behavior should be observed as expansion, the measurement shows the shrinkages, hence the results, it is possible that these shrinkages are coated part of steel due to softening. The change amount of coated steel is consisted of the base material expansion and the change of coating material, thus the base material, steel, is placed at the reference, the measurement result can be subtracted the base material's expansion from coated steel.

The high-sensitivity differential penetration method is available to evaluate the coated material due to subtract the base material expansion from it.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.