Lead-free Solder

Scope

The measurement of lead in lead-free solder is demonstrated by rapid XRF screening for Restriction on Hazardous Substances (RoHS), Waste Electrical and Electronic Equipment (WEEE) and End of Life Vehicles (ELV) directives.

Background

Lead (Pb) content is limited in most solder applications according to regulations RoHS, WEEE and ELV initiatives. These regulations limit the maximum allowable Pb in solder to no greater than 0.1000% Pb (1000 ppm). Energy Dispersive X-ray Fluorescence (EDXRF) is an accepted analysis technique for the rapid screening to determine whether Pb is below allowable limits. Fast and simple to operate, the NEX DE VS system offers screening for Pb content and use of camera view and automatic small spot collimators down to 1 mm spot size, making it an ideal tool for rapid screening to ensure regulation compliance.

Model: NEX DE VS

Model: NEX DE VS

Small spot analysis — RoHS, WEEE, and ELV rapid screening by XRF

NEX DE VS using camera view and automatic collimators is ideally equipped for the screening of samples to check compliance with RoHS, WEEE, and ELV. For this type of screening the FP approach is used.

Fundamental parameters (FP) with matching library

Rigaku RPF-SQX fundamental parameters was used for the application using the pre-defined Metal template. A simple 2-point Matching Library is easily created to specifically define the Pb-free solder application using the 1 mm small spot collimator.

| MBH Analytical, Ltd. 74X CA2 (batch 2) Units: mass% 1 mm collimator |

||

| Element | Reference value | NEX DE VS result |

| Pb | 0.0496 | 0.0501 |

| Sn | Balance | 93.853 |

| Ag | 3.50 | 3.333 |

| Cu | 0.795 | 0.761 |

| Bi | 0.0365 | 0.0405 |

| Fe | 0.0023 | ND |

| As | 0.018 | 0.017 |

Measurement results of loaded PCB

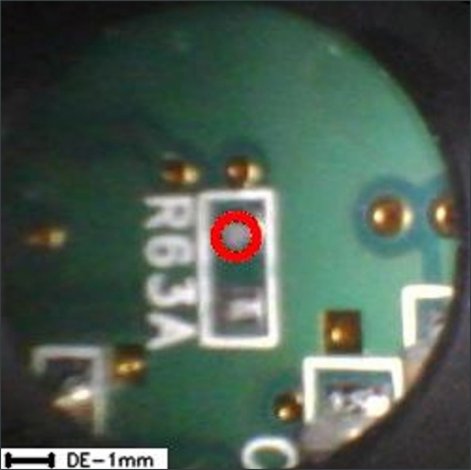

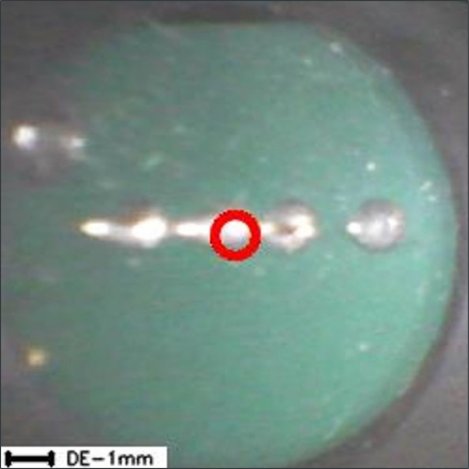

To demonstrate use of the small spot capability and camera view, solder joints on two loaded printed circuit boards (PCB) were tested using the 1 mm collimator.

PCB 1: PCB with Pb-free solder

| PCB 1 | Units: mass % |

| Element | NEX DE VS Result |

| Pb | ND* |

*Not Detected

PCB 2: PCB with high Pb

| PCB 2 | Units: mass % |

| Element | NEX DE VS result |

| Pb | 1.68 |

Sensitivity

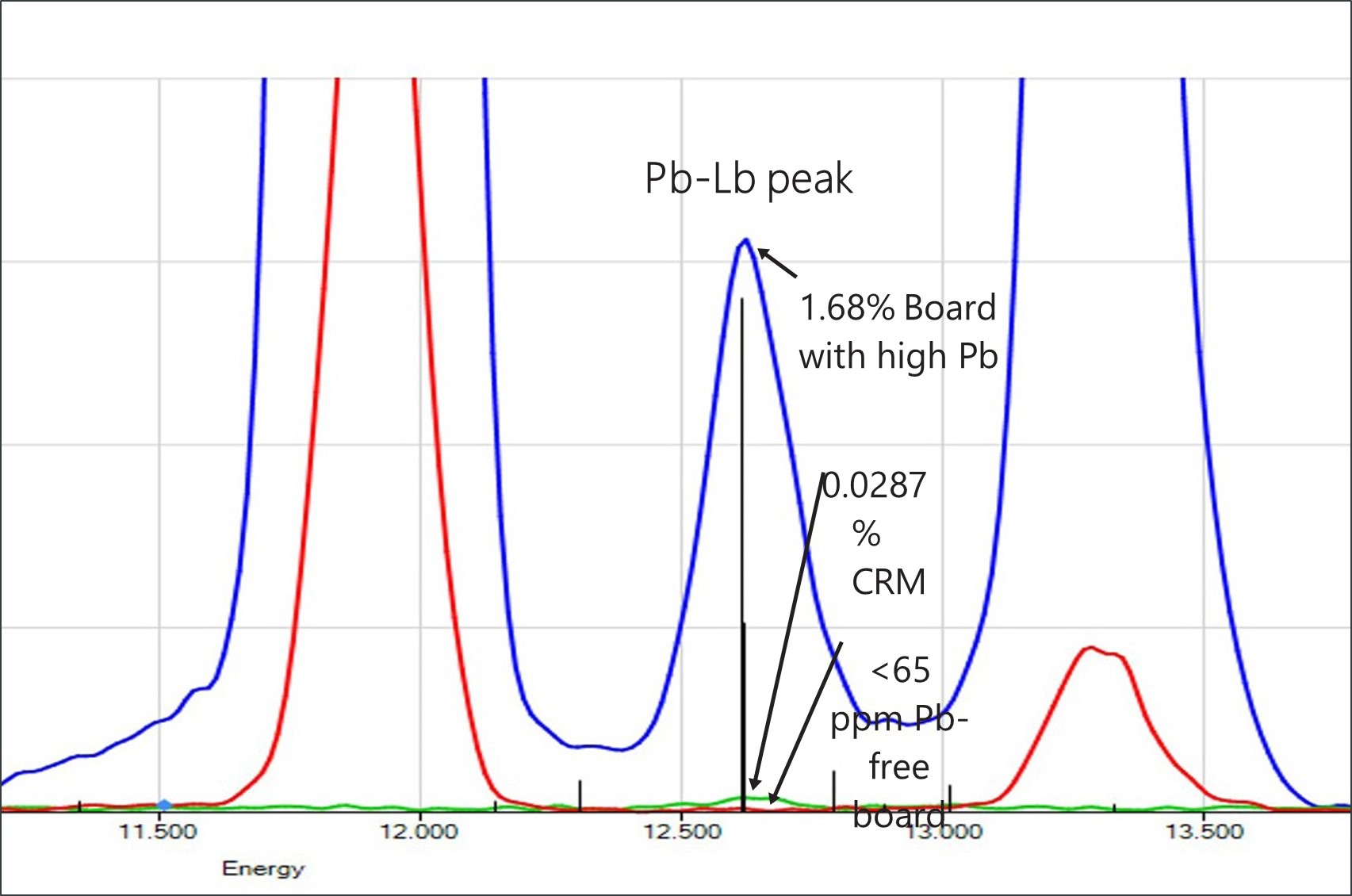

The combination of 60 kV X-ray tube, high-throughput SDD detector and special tube filters gives NEX DE VS exceptional sensitivity for Pb, as well as other middle and heavy elements. Excellent sensitivity to the measurement of Pb is shown.

Comparison of high Pb board, CRM and Pb-free board. Peaks to left and right of the Pb peak are from the Br flame retardant coating applied to PCBs.

- Red Spectrum: PCB Pb-free solder showing no Pb

- Green Spectrum: Certified reference standard MBH Analytical 74X CA6 batch B, 0.0287% Pb

- Blue Spectrum: PCB with high Pb, 1.68% Pb

Conclusion

The NEX DE VS with automatic collimators and camera provides excellent resolution and sensitivity for rapid screening by XRF for compliance with RoHS, WEE and ELV initiatives.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.