SmartLab

Automated Multipurpose X‑ray Diffractometer (XRD) With Guidance Software

Powder diffraction, thin film metrology, SAXS, in-plane scattering, operando measurements

Rigaku SmartLab is the newest and most novel high-resolution X-ray diffractometer (XRD) available today. Perhaps its most novel feature is the new SmartLab Studio II software, which provides the user with an intelligent User Guidance expert system functionality that guides the operator through the intricacies of each experiment. It is like having an expert standing by your side.

SmartLab Overview

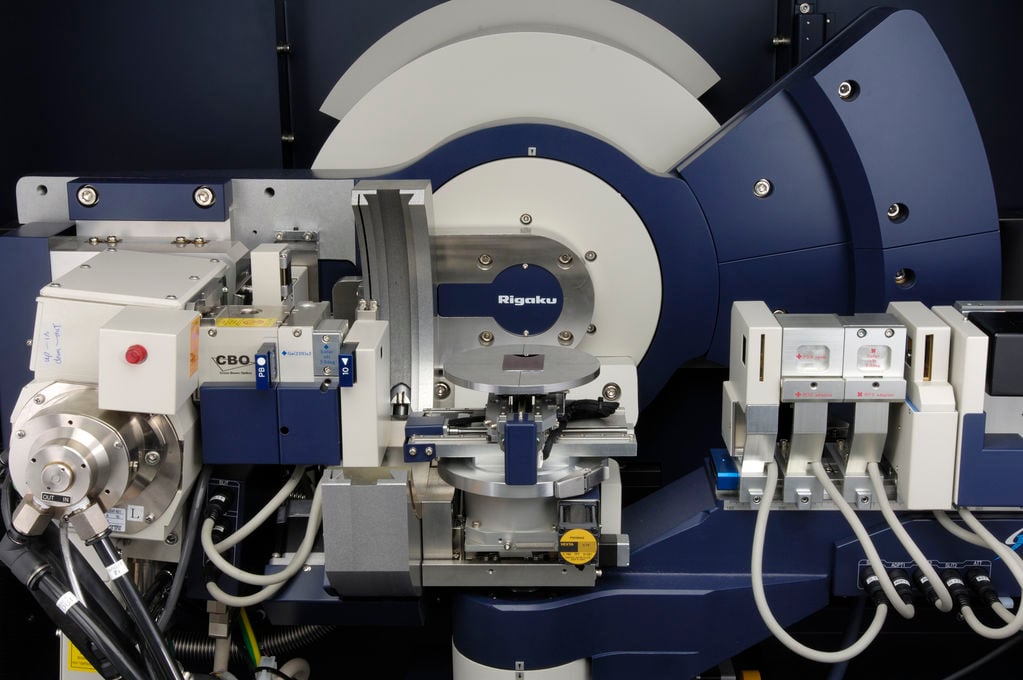

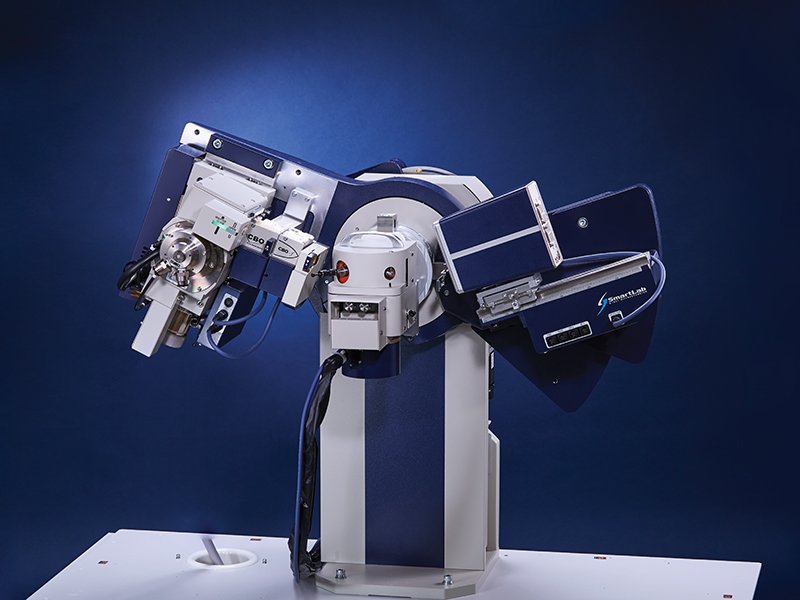

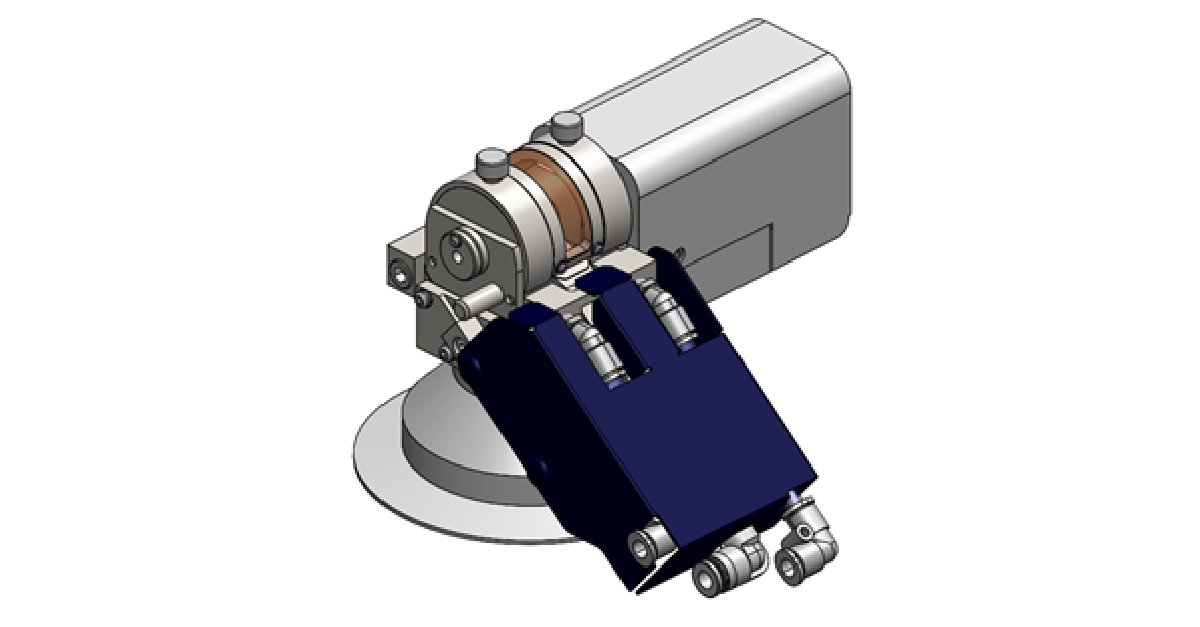

This new X-ray diffraction system features the PhotonMax high-flux 9 kW rotating anode X-ray source coupled with a HyPix-3000 high-energy-resolution 2D multidimensional semiconductor detector that supports 0D, 1D and 2D measurement modes, allowing all applications to be handled with a single detector, eliminating the inconvenience of preparing and switching individual detectors for different applications. The HyPix-3000 detector can be used to obtain 2D powder diffraction patterns, which can be processed to deliver superior qualitative analysis by using all the 2D pattern information. The system incorporates a high-resolution θ/θ closed loop goniometer drive system with an available in-plane diffraction arm. The system’s new Cross-Beam-Optics (CBO) family feature fully automated switchable reflection and transmission optics (CBO-Auto).

XRD designed for usability

Coupling a computer controlled alignment system with a fully automated optical system, and the User Guidance functionality within the SmartLab Studio II software, makes it easy to switch between hardware modes, ensuring that your hardware complexity is never holding back your research.

XRD that is functionality redefined

Whether you are working with thin films, nanomaterials, powders, or liquids the SmartLab will give you the XRD functionality to make the measurements you want to make when you want to make them. The equipment accepts powder, liquid, films, and even textile samples and allows mapping measurements within suitable samples. Operando (a.k.a., real time in-situ) measurements can be performed with the new Rigaku SmartLab Studio II software suite, which is an integrated software platform incorporating all functions from measurement to analysis. The system also features robust security and validation protocols to ensure that any technology component - software or hardware - fulfills its purpose within regulatory guidelines, including 21 CFR Part 11, establishing the US EDA regulations governing electronic records and electronic signatures (ER/ES).

SmartLab Features

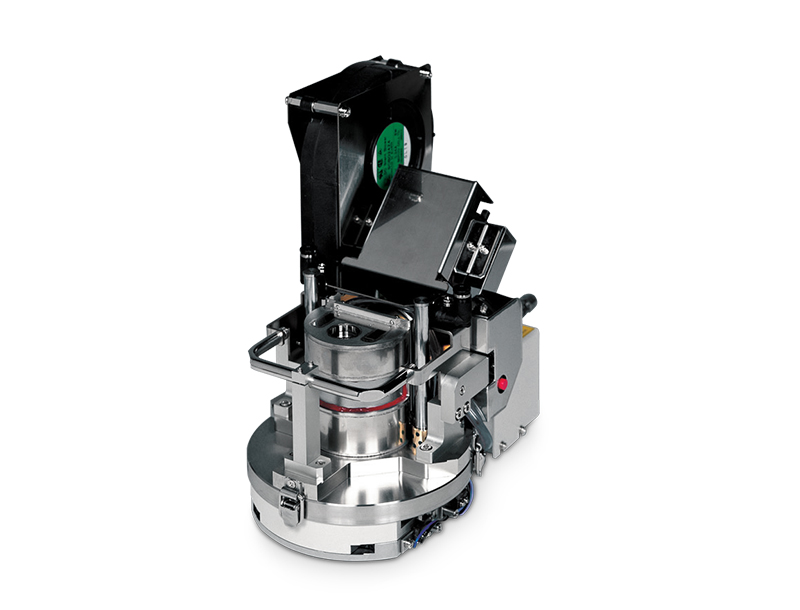

High-resolution micro area CBO-μ

SmartLab Videos

SmartLab Specifications

| Technique | X-ray diffraction (XRD) | |

|---|---|---|

| Benefit | Powder diffraction, thin film, SAXS, in-plane scattering, operando measurements | |

| Technology | Automated high-resolution θ-θ multipurpose X-ray diffractometer (XRD) with expert system Guidance software | |

| Attributes | 3 kW sealed X-ray tube CBO optics D/teX Ultra 250 silicon strip detector |

|

| Options | PhotonMax high-flux 9 kW rotating anode X-ray source In-plane arm (5-axis goniometer) HyPix-3000 high energy resolution 2D HPAD detector Johansson Kα₁ optics |

|

| Computer | External PC, MS Windows OS, SmartLab Studio II software | |

| Dimensions | 1300 (W) x 1880 (H) x 1300 (D) mm | |

| Mass | Approx. 750 kg (sealed tube) 850 kg (rotating anode) |

|

| Power requirements | 1Ø, 200-230 V 50/60 Hz, 40 A or 3Ø, 200 V 50/60 Hz, 30 A (sealed tube) 3Ø, 200 V 50/60 Hz, 60 A (rotating anode) |

|

SmartLab Options

The following accessories are available for this product:

SmartLab Application Notes

The following application notes are relevant to this product

-

XRD2001 - Orientation and Residual Stress Evaluation in Metal Thin Films

-

BATT1018 - XRD Measurement with Temperature Control and Charge/Discharge Using Laminated Cells

-

BATT1017 - XRD Measurement during Charge/Discharge Using All-Solid-State Batteries

-

BATT1016 - XRD Measurement During Charge/Discharge Using Laminated Cell Batteries

-

BATT1015 - Local Structure Analysis of Li₃PS₄ Solid-State Electrolyte

-

BATT1012 - Inference of Valence and Li Ion Diffusion Path Using the BVS Method

-

BATT1011 - Measurement of Cathode Material NCM Using XSPA-400 ER High-Energy Resolution Detector

-

BATT1010 - Investigation of Phase Transition Behavior upon Cathode Material NCM Firing

-

PHRM0002 - In-Situ DSC-Humidity PXRD Analysis for Pharmaceuticals

-

BATT0003 - Battery Performance

-

BATT0002 - Battery Material Characterization

-

BATT0001 - Battery Material Development

-

B-XRD1143 - Verifying the Validity of Crystallite Sizes Determined by the FP Method

-

B-XRD1129 - Variable Humidity Measurement of a Drug Substance using XRD-DSC and a Humidity Controller

-

B-XRD2034 - Twist Width Evaluation of Group III-V Nitride Films by Rocking Curve Measurement

-

B-XRD1109 - Structure Determination of Ferroelectric Nano-powder by PDF Analysis

-

B-XRD1131 - Structural Characterization of Zeolite by PDF Analysis

-

B-XRD1136 - Structural Characterization of Zeolite by Electron Density Analysis

-

B-XRD1112 - Structural Analysis of Amorphous Silica by PDF Analysis

-

B-XRD1123 - Simultaneous Operando XRD Measurement for Positive and Negative Electrode Materials

-

B-XRD1080 - Rietveld Analysis of Battery Material using a Mo Source

-

B-XRD1118 - Quick Pole Figure Measurement of a Metal Material using 2DD

-

B-XRD1119 - Quantitative Characterization of Polymer film by Orientation Function

-

B-XRD1120 - Quantitative Analysis of Pharmaceutical Polymorphic Forms via the DD Method

-

B-XRD1115 - Quantitative Analysis of γ-Al₂O₃ by the DD Method

-

B-XRD1132 - Quantitative Analysis of Glass with the DD Method

-

B-XRD1142 - Quantitative Analysis of Crystal Polymorphs by the DD Method

-

B-XRD1093 - Quantitative Analysis of Amorphous Components in Cement

-

B-XRD1001 - Quantitative Analysis of a 4-component Sample

-

B-XRD1111 - Quantitative Analysis of 3-component Sample by DD method

-

B-XRD1125 - Quantification of the Taste of Salt by DD (Direct Derivation) Method

-

B-XRD1146 - Quantification of Blast Furnace Slag by Rietveld Refinement using Reference Intensity Ratio

-

B-XRD1002 - Quantification of a 4-component Sample using RIR method

-

B-XRD1043 - Powder Crystal Structure of Organic Crystals

-

B-XRD1121 - Phase Identification of Mixed Powder by Real-time Analysis

-

B-XRD2023 - Phase Identification of an Organic Thin Film by GIWAXS Measurement with a 2D detector

-

B-XRD1103 - Phase Identification of a Coarse-grained Trace Component in a Mineral Powder using 2D XRD

-

B-XRD2020 - Phase ID and Orientation Analysis for Thin Film SOFC Material using 2DD

-

B-XRD1137 - Phase ID Analysis of Micro-impurities on the Surface of a Tablet by Micro-area XRD Measurements

-

B-XRD1021 - Phase Changes of Pharmaceuticals as a Function of Temperature and Humidity

-

B-XRD1110 - Particle Size Distribution Analysis of Ferroelectric Nanopowder by USAXS

-

B-XRD1102 - Particle Size / Distribution of Pigment Ink by USAXS

-

B-XRD1030 - Particle Diameter Distribution of Gold Nanoparticles

-

B-XRD2009 - Orientation Analysis of Organic Thin Film on Single Crystal Sub by In-plane XRD

-

B-XRD2005 - Orientation Analysis of Organic Thin Film on Rubbed Glass by In-plane XRD

-

B-XRD1124 - Operando Transmission XRD Measurement of All-solid-state Lithium-ion Battery using Ag Source

-

B-XRD1116 - Operando Measurement of Laminated Lithium-ion Battery using 2DD

-

B-XRD2028 - Off-normal Fiber Texture Analysis by Pole Figure Measurement

-

B-XRD2032 - Observation of Orientation State of Polypropylene Film Products by 2D-GIWAXS Measurement

-

B-XRD1020 - Observation of Dehydration Process of Hydrate by XRD-DSC

-

B-XRD1128 - Observation of Dehydration Behavior of a Drug Substance using TG-DTA and XRD-DSC

-

B-XRD1026 - Observation of Crystallization Behavior of Ionic Liquids by XRD-DSC

-

B-XRD1135 - Observation of Butter Crystal by Simultaneous XRD-DSC Measurement

-

B-XRD1117 - Observation of a Phase Transition at High Temperature under Various Atmospheres

-

B-XRD1089 - Micro-area Mapping Measurement of Printed Circuit Boards

-

B-XRD1023 - Measurement of Pseudo-polymorph Impurities in Tablets

-

B-XRD1063 - Measurement of a Film Sample

-

B-XRD1107 - Material Characterization by PDF and RDF Analysis

-

B-XRD2003 - Magnetic Recording Media (FePt) by In-plane XRD

-

B-XRD1114 - LOQ of Trace Impurities in API by the DD Method

-

XRD1003 - How to Evaluate Solid Pharmaceutical Drugs (3): Confirming Hydrates

-

XRD1002 - How to Evaluate Solid Pharmaceutical Drugs (2): Confirming the Presence/absence of Amorphous Substances

-

XRD1001 - How to Evaluate Solid Pharmaceutical Drugs (1): Confirming the crystal form of an API

-

B-XRD1105 - High-speed in-situ Measurement of Melting Process of Metal

-

B-XRD1147 - High-precision Quantitative Analysis of Clinker Mineral Polymorphs by Rietveld Refinement

-

B-XRD2021 - High-speed RSM of an Epitaxial Film by 1D Detection Mode

-

B-XRD2024 - High-speed RSM of a III-nitride Epitaxial Film by 1D Detection Mode

-

B-XRD2007 - Examination for Growth Process of Organic Thin Film by In-plane XRD

-

B-XRD2030 - Evaluation of Uniformity of Thin Film Thickness by X-ray Reflectivity Mapping

-

B-XRD2027 - Evaluation of Uniformity of a Single CrystalSubstrate by Rocking Curve Measurement

-

B-XRD1122 - Evaluation of the Crystallinity of a Carious Tooth using X-ray Diffraction

-

B-XRD3005 - Evaluation of Residual Stress of Thin Films by GI-XRD and the Multiple hkl Method

-

B-XRD1113 - Evaluation of Oxidation State by the BVS Method

-

B-XRD1150 - Evaluation of Graphitization Degree of Lithium-ion Battery Carbon Anode Material by X-ray Diffractometry

-

B-XRD1104 - Evaluation of Grain Condition and Orientation of Cemented carbide using 2D XRD

-

B-XRD2031 - Evaluation of Curvature of a Single Crystal Substrate by Rocking Curve Measurement

-

B-XRD1078 - Evaluation of Crystallite Size and Pore Size distribution of Fuel Cell Materials

-

B-XRD2001 - Evaluation of Crystal Quality (Tilt and Twist Qidths) of Group-III Nitride Film by the Rocking Curve Method

-

B-XRD1149 - Evaluation of Barium Titanate Polymorphs by Rietveld Analysis

-

B-XRD1108 - Direct Observation of Melting and Crystallization of Fresh Cream

-

B-XRD1126 - Crystallization of Chocolate Observed by XRD-DSC

-

B-XRD1018 - Crystallite Size Distribution of Zinc Oxide Nanoparticles

-

B-XRD1071 - Crystallite Size Analysis of a Catalyst Material by the Scherrer Method

-

B-XRD1035 - Crystal Structure Analysis of a Powder Sample of Pharmaceutical Cocrystals by the Rietveld Method

-

B-XRD1046 - Crystal Phase Identification of Pharmaceutical Materials in the Freeze Drying Process

-

B-XRD1044 - Crystal Phase Identification of Carbide Tips by Micro-area 2D X-ray Diffraction

-

B-XRD2006 - Crystal Orientation Evaluation of Epitaxial Film and Ultrathin Buffer Layers by In-plane Reciprocal Space Mapping

-

B-XRD1014 - Crystal Orientation Analysis of Rolled Sheet Material by Pole Figure Measurement

-

B-XRD2022 - Crystal Defect Analysis by X-ray Reflection Topography

-

B-XRD1009 - Charging-discharging of Cathode Materials in Li-ion Batteries

-

B-XRD1106 - Charge/discharge Process of Li-ion Battery Positive Electrode

-

B-XRD1139 - Calculation of Molecular Stacking Spacing of Copper Phthalocyanine using PDF Analysis

-

B-XRD2025 - Analysis of Uniaxially Oriented Film by Wide-range RSM

-

B-XRD2026 - Analysis of Epitaxial Films on In-plane Anisotropic Substrates by Wide-Range RSM

-

B-XRD1141 - Accurate and Highly Precise Quantitative Analysis of Cement Samples using Rietveld Refinement

-

B-XRD1140 - Accurate and Highly Precise Quantitative Analysis of Cement Samples using Rietveld Refinement

-

B-XRD1011 - Temperature Dependence of a Lattice Constant

SmartLab Resources

Webinars

Visit the Webinar resource page to access Webinars relevant to SmartLab

Rigaku Journal articles

Visit the Rigaku Journal resource page to access articles relevant to SmartLab

Publications

Visit the Publication Library to access articles relevant to SmartLab

SmartLab Events

Learn more about our products at these events

-

EventDatesLocationEvent website

-

SPIE Advanced Lithography + PatterningFebruary 22 2026 - February 26 2026San Jose, CA, USA

-

13th European NESY WinterschoolFebruary 22 2026 - February 27 2026Bad Aussee, Austria

-

Florida Semiconductor SummitFebruary 23 2026 - February 25 2026Orlando, FL, USA

-

34th Annual Meeting of the German Crystallographic Society (DGK)February 25 2026 - February 28 2026Lübeck, Germany

-

37. Deutsche Zeolith-Tagung in StuttgartFebruary 25 2026 - February 27 2026Stuttgart, Germany

-

Rigaku Taiwan professional training courses (SCX)February 26 2026 - February 26 2026Rigaku Taiwan (RTC-TW)

-

Prospectors & Developers Assoc of Canada 2026March 1 2026 - March 4 2026Toronto, ON, Canada

-

DKT 2026March 3 2026 - March 6 2026Karlsruhe, Germany

-

Rigaku UK User Meeting 2026March 4 2026 - March 5 2026Oxfordshire, UK

-

Pittcon 2026March 9 2026 - March 11 2026San Antonio, TX, USA

-

HäKo 2026March 11 2026 - March 13 2026Bonn, Germany

-

JSAP Spring Meeting 2026March 15 2026 - March 16 2026Tokyo, Japan

-

The 2026 International Conference on Frontiers of Characterization and Metrology for Nanoelectronics (FCMN) Platinum SponsorsMarch 16 2026 - March 19 2026Monterey, CA ,USA

-

APS 2026March 16 2026 - March 20 2026Denver, CO, USA

-

ACS Spring 2026March 22 2026 - March 26 2026Atlanta, GA, USA

-

International Battery 2026March 23 2026 - March 26 2026Orlando, FL, USA

-

AnalyticaMarch 24 2026 - March 27 2026Munich, Germany

-

SEMICON China 2026March 25 2026 - March 27 2026SNIEC, Shanghai, China

-

Rigaku Taiwan professional training courses (XRD)March 27 2026 - March 27 2026Rigaku Taiwan (RTC-TW)

-

BCA Spring Meeting 2026March 30 2026 - April 1 2026Leeds, United Kingdom

-

Chembio ExhibitionApril 15 2026 - April 16 2026Helsinki, Finland

-

CS International 2026April 20 2026 - April 22 2026Brussels, Belgium

-

MRS Spring 2026April 26 2026 - May 1 2026Hawaii, HI, USA

-

COPS XII - 12th International Symposium on the Characterization of Porus SolidsMay 4 2026 - May 6 2026Dresden, Germany

-

SEMICON SEA 2026May 5 2026 - May 7 2026Kuala Lumpur, Malaysia

-

ASMC – Advanced Semiconductor Manufacturing ConferenceMay 11 2026 - May 14 2026Albany, NY, USA

-

Metal-Organic Frameworks Workshop 2026May 17 2026 - May 20 2026New Orleans, LA, USA

-

Canadian Chemistry Conf 2026May 24 2026 - May 28 2026Toronto, ON, Canada

-

WOCSDICE/EXMATEC 2026May 24 2026 - May 28 2026Gdańsk, Poland

-

E-MRS 2026 Spring MeetingMay 25 2026 - May 29 2026Strasbourg, France

-

The 2026 IEEE 76th Electronic Components and Technology ConferenceMay 26 2026 - May 29 2026Orlando, Fl, USA

-

ICDD Summer School 2026June 1 2026 - June 5 2026Newton Square, PA

-

ACA Summer School 2026June 7 2026 - June 14 2026West Lafayette, IN, USA

-

PorMat 2026June 9 2026 - June 10 2026Bristol, UK

-

Physics of Magnetism 2026June 22 2026 - June 26 2026Poznan, Poland

-

DSL-2026 ConferenceJune 22 2026 - June 26 2026Rhodes, Greece

-

CEIA Leti Innovation DaysJune 23 2026 - June 25 2026Maison Minatec, Grenoble, France

-

EPDIC 19June 23 2026 - June 26 2026Crans Montana, Switzerland

-

Mineralogical Society at 150: Past Discoveries and Future FrontiersJune 23 2026 - June 25 2026Manchester, UK

-

Polish Crystallographic Meeting + OlympicJune 24 2026 - June 26 2026Wroclaw, Poland

-

The International Workshop on Gallium Oxide and Related Materials (IWGO-6)August 2 2026 - August 7 2026College Park, MD, USA.

-

International workhop on Gallium Oxide 2026August 2 2026 - August 8 2026College Park, MD

-

Denver X-ray Conference (DXC) 2026August 3 2026 - August 7 2026Lombard, IL, USA

-

12th Pacific Rim International Conference on Advanced Materials and Processing (PRICM12)August 9 2026 - August 13 2026Gold Coast Queensland, Australia

-

27th Congress and General Assembly of the IUCrAugust 11 2026 - August 18 2026Calgary, Alberta, Canada

-

ACS Fall 2026August 23 2026 - August 27 2026Chicago, IL, USA

-

SEMICON Taiwan 2026September 2 2026 - September 4 2026Taipei, Taiwan

-

ICSCRM Japan 2026 (Silver Sponsor)September 27 2026 - October 2 2026Yokohama, Japan

-

MS&T 2026October 4 2026 - October 7 2026Pittsburgh, PA, USA

-

GSA 2026October 11 2026 - October 14 2026Denver, CO, USA

-

Battery Show 2026October 12 2026 - October 15 2026Detroit, MI, USA

-

SEMICON West 2026October 13 2026 - October 15 2026San Francisco, CA, USA

-

Gulf Coast Conference (GCC) 2026October 13 2026 - October 15 2026Galveston, TX, USA

-

AAPS PharmSci 360 - 2026October 25 2026 - October 28 2026New Orleans, LA, USA

-

SERMACS 2026November 4 2026 - November 7 2026Memphis, TN, USA

-

SEMICON EuropaNovember 10 2026 - November 13 2026Munich, Germany

-

Eastern Analytical Symposium (EAS) 2026November 16 2026 - November 18 2026New Jersey

-

MRS Fall 2026November 29 2026 - December 4 2026Boston, MA, USA

-

Advanced Automotive Battery Conf 2026December 8 2026 - December 11 2026Las Vegas, NV, USA

-

SEMICON Japan 2026December 9 2026 - December 11 2026Tokyo, Japan

SmartLab Training

Upcoming training sessions

-

TitleDatesCostLocationNotesCourse outlineRegistration form

-

SmartLab training (EMEA)March 8 2026 - March 12 2026Please contact ECOE@rigaku.comNeu-Isenburg, GermanySmartLab training (EMEA)

-

SmartLab training (EMEA)June 28 2026 - July 2 2026Please contact ECOE@rigaku.comNeu-Isenburg, GermanySmartLab training (EMEA)

-

SmartLab training (EMEA)October 18 2026 - October 22 2026Please contact ECOE@rigaku.comNeu-Isenburg, GermanySmartLab training (EMEA)

SmartLab

Testimonials

-

In our technological environment, especially in semiconductor applications, there is a strong need for advanced thin film characterization. The SmartLab’s high-brilliance rotating anode source, combined with versatile 1D and 2D detectors and in-plane diffraction capabilities, makes it an essential tool for our research.

Read the full testimonialDr. Frédéric FillotX-ray & Materials AnalysisCEA-Leti & PFNC, Grenoble, France -

I'd strongly recommend the system: it truly is easy to get to grips with, even for a non-specialist. The software guidance and simple hardware fittings are a game-changer for hands-on use.

Read the full testimonialJoseph WrightUniversity of East Anglia -

Big advantage of SmartLab is in simple and rapid change between individual diffractometer configurations followed by automated and reliable optics and sample alignments. This possibility together with high photon flux of rotating anode source significantly increased the throughput of our laboratory, increased the number of measured samples together with the high quality of measured data.

Read the full testimonialMilan DopitaCharles University -

The big advantages of the instrument are especially the in-plane arm, allowing for non-coplanar X-ray diffraction measurements without tilting the sample, and easy procedures for X-ray optics exchange and realignment.

Read the full testimonialOndřej CahaMasarykova univerzita -

From a technical standpoint, I believe that the 9 kW rotating anode and the multitude of degrees of freedom are the innovative elements that can make the difference with other X-ray diffraction equipment.

Read the full testimonialPhD Cosmin RomanițanNational Institute for Research and Development in Microtechnologies (IMT)

Nanobiotechnology Laboratory

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.