Application Note B-XRD1103

Introduction

Grain sizes dramatically influence observed 2D XRD images, with fine grains appearing as rings and coarse grains as spots. In the classical approach, XRD software only attempted crystal phase identification after converting the 2D diffraction image to a 1D profile. Information about grain conditions in the 2D diffraction image was not used. The Powder XRD plugin for SmartLab Studio II uses both the 2D diffraction image and a 1D profile derived from it for analysis. Using information about crystal grains obtained from 2D diffraction images for search/match, phase identification can be done easily.

Measurements and results

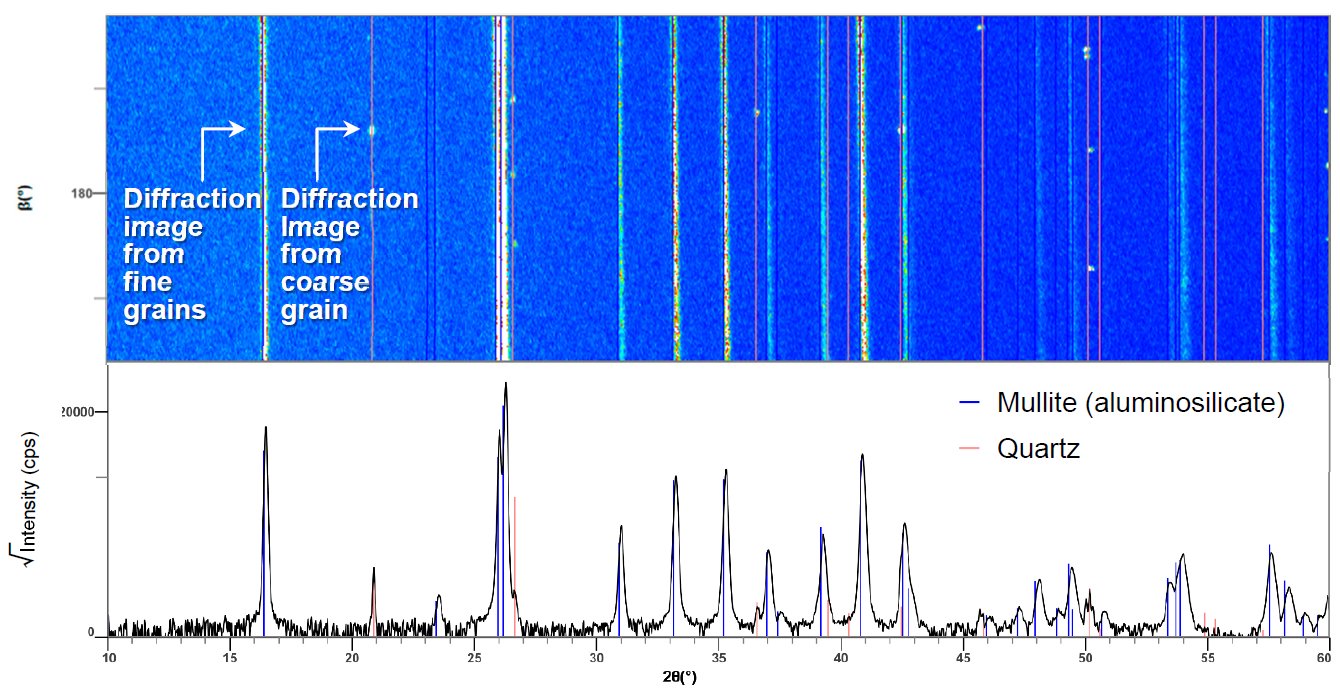

Figure 1 shows a 2D diffraction image and the associated 1D profile with phase identification results from a mineral powder. Lines and spots can be seen in the 2D diffraction image. This indicates that the sample includes components with different grain conditions.

The line-shaped diffraction patterns were identified as mullite and the dotted diffraction patterns were identified as quartz. The ratio of intensities of the peaks in the 1D profile of quartz was vastly different from the standard ratio in the powder diffraction database. The intensity around 2θ=55˚ was too weak to observe as a diffraction peak. Using information derived from the spots present in the 2D diffraction image, phase identification was easily performed, even for a challenging case like this.

Figure 1: 2D diffraction image and 1D profile with phase identification results of a mineral powder.

Figure 1: 2D diffraction image and 1D profile with phase identification results of a mineral powder.