High-speed in-situ Measurement of Melting Process of Metal

Introduction

To capture the moment when materials change, such as during melting, solidification, amorphization or crystal phase change, by in-situ X-ray diffraction measurement, the acquisition time of the X-ray diffraction images at each temperature needs to be as short as possible. The HyPix-3000 hybrid pixel array multi-dimensional detector in 2D mode can acquire X-ray diffraction images without a scan, and makes it possible to observe rapid changes in crystalline state.

Measurements and results

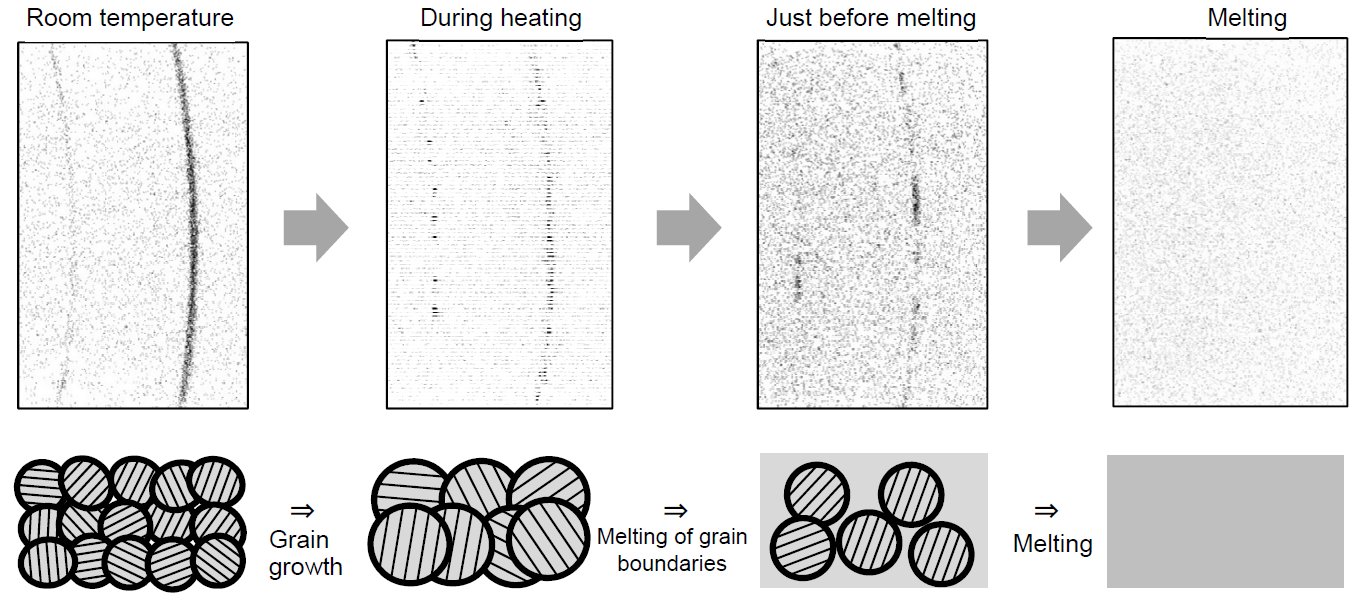

2D X-ray diffraction images of an Al plate sample were recorded every 0.5 seconds while rapidly increasing the temperature at 300˚C/min. Figure 1 shows the 2D X-ray diffraction images and schematic views of the crystalline state suggested by their features. Continuous Debye rings from the Al plate were observed at room temperature. This means that the Al crystal had fine grains before heating. During the increase in temperature, the Debye rings became dotted, indicating that grain growth occurred due to heating. When the temperature was increased even further, the Debye rings eventually disappeared due to the melting of Al. It was confirmed that there was a temperature range where the continuity of the Debye rings increased just before melting. This was the moment when the grain boundaries of Al melted and the liquid phase and minute crystal grains of Al coexisted.

Figure 1: 2D X-ray diffraction images observed during high-speed temperature increase in-situ measurement of Al metal, and schematic diagrams of changes in crystal grains.

Related products

SmartLab

Advanced state-of-the-art high-resolution XRD system powered by Guidance expert system software

Learn More

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.

/SmartLab%20Studio%20II%20splash%20screen.png?width=800&height=610&name=SmartLab%20Studio%20II%20splash%20screen.png)