Application Note B-XRD1132

Introduction

In powder X-ray diffractometry, the weight fraction (content) of amorphous materials is obtained using the peak separation method or the Rietveld method. However, the solution from the peak separation method has large errors in some cases, and the Rietveld refinement requires adding a standard sample to the measurement sample. The Direct Derivation (DD) method developed by Rigaku is able to directly calculate the amorphous content from single-phase and mixed-phase measurement data. The following is an analysis example using the DD method, in which the contents of a mixture containing glass powder and two different types of crystal powder were calculated.

Measurements and results

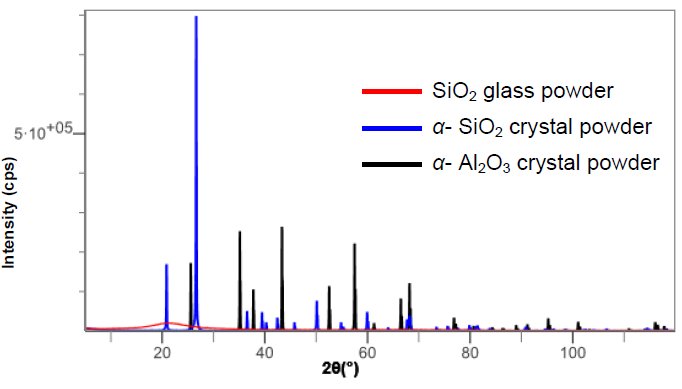

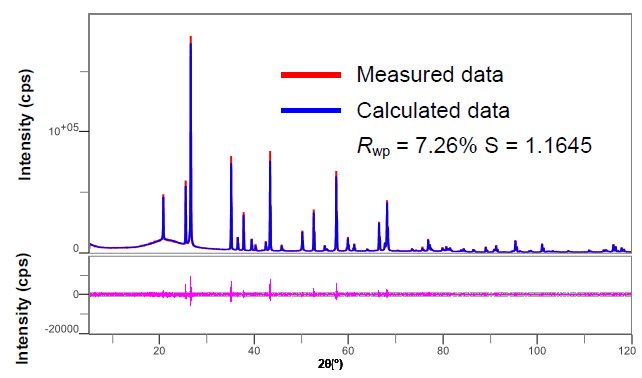

First, SiO₂ glass (amorphous) powder, α-SiO₂ crystal powder and α-Al₂O₃ crystal powder were mixed at the ratio of 50:20:30. Then an X-ray diffraction profile of the mixture was measured and its weight fraction was calculated by the whole powder pattern fitting (WPPF) method. Figure 1 shows single-phase X-ray diffraction patterns of SiO₂ glass powder, α-SiO₂ crystal powder and α-Al₂O₃ crystal powder. A sharp peak was obtained from the crystal powder and a broad halo pattern was obtained from the glass powder. Figure 2 shows the result of WPPF with the DD method applied to the measured data of the mixture. The measured data and the calculated data fit well. Table 1 shows Rwp, S, and prepared and quantitative values of the mixture contents as the analysis results. These results indicate that the amorphous content can be calculated directly from the measured data of the single phase and mixed phase.

Figure 1: Single phase X-ray diffraction pattern of three components

Figure 2: Result of WPPF with the DD method applied to the mixture data

Table 1: Rwp and S of the fitting, and prepared and quantitative values of the mixture

| SiO glass (amorphous) | α-SiO₂ crystal powder | α-Al₂O₃ crystal powder | |

| Rwp (%) | 7.32 | ||

| S | 1.1741 | ||

| Prepared value (mass%) | 49.91 | 20.06 | 30.02 |

| Quantitative value (mass%) | 50.18(5) | 20.46(4) | 29.36(5) |

References

(1) H. Toraya: J. Appl. Cryst., 49 (2016) 1508-1516.

(2) H. Toraya: J. Appl. Cryst., 50 (2017) 820-829.