Background

In a strictly regulated industry, cement producers must maintain manufacturing processes that are accurate, running efficiently, and thus ensure that their customers receive the highest quality material ideally suited for a specific application. So a cement plant must continuously analyze its products to meet these requirements. The ability to accurately analyze for the major components as well as for minute concentrations of light elements (as low as sodium) has recently been demonstrated on the Rigaku Supermini200 benchtop WDXRF spectrometer. This small unit uses a 200 W Pd X-ray tube, has a 12-position sample carousel for automated analysis, and an air-cooled X-ray tube, which eliminates the need for cooling water or a chiller.

The performance goals met by the Supermini200 are those set forth in ASTM C114 : Standard Test Methods for Chemical Analysis of Hydraulic Cement. Overall C114 is a measure of both the analyzing system's stability and the user's ability at sample preparation—the sample must be repeatedly produced as a pressed pellet or fused disk and show only very small analytical variations, the assumption being that if both instrument stability and sample preparation are optimized then a linear calibration will be achieved using reference materials such as NIST Portland Cements and both accuracy and precision will be within the ASTM method specifications. Reference materials used consisted of the NIST Certified materials 1880a, 1881a, 1884a, 1885a, 1886a, 1887a, 1888a, 1889a.

Investigation

The initial test was performed using fused disks supplied by the Arkansas Department of Transportation. The fusion recipe consisted of a 1:10 dilution of sample into a 50:50 lithium salt flux. An analytical routine was created on the Supermini200 using the NIST Certified Reference Materials (CRMs). One of the CRMs (1884a), prepared in duplicate, was run as an unknown to determine if the Supermini200 could comply with C114.

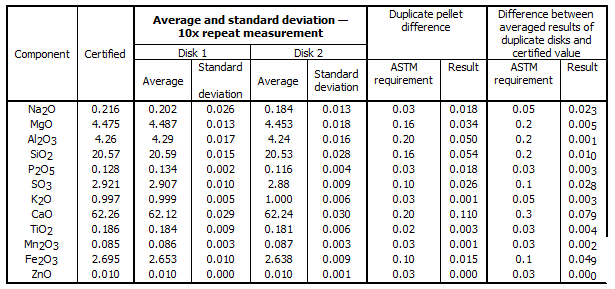

The following tables demonstrate the results for these runs in accordance to C114 specifications.

| Component | Range (mass%) | Component | Range (mass%) |

| CaO | 57.58~67.87 | TiO2 | 0.084~0.366 |

| SiO2 | 18.637~22.38 | Na2O | 0.021~1.068 |

| Al2O3 | 3.875~7.06 | P2O5 | 0.022~0.306 |

| Fe2O3 | 0.152~3.09 | Mn2O3 | 0.007~0.259 |

| SO3 | 2.086~4.622 | Cl | 0.0019~0.013 |

| MgO | 0.814~4.475 | ZnO | 0.001~0.107 |

| K2O | 0.093~1.228 |

Standard Error (SE) results:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:

SE is a measure of the goodness of a specific calibration (as shown in the equation to the right), the average difference (in unit concentration) between the suggested standard values and their proximity to calculated calibration line where σest is the SE, Y is the value of a calibration standard, Y' is measured value of a calibration standard, and N is the number of calibration standards employed.

Each of the duplicate samples were run 10x on the Supermini200. All tests cycled the disk in and out of the XRF system between analysis runs.

Conclusion:

ASTM C114 requirements can easily be achieved using this benchtop WDXRF system. Benefits from the Supermini200 obviously are efficient use of space and comparative ease of operation. These benefits, plus minimum service requirements, lower initial financial outlay and lower ongoing cost of ownership, make the Supermini200 an ideal solution for cement analysis by XRF.