Background

It is common that physically and chemically deposited thin films on substrates exhibit inhomogeneity along the growth direction. For many thin film materials, the film-on-substrate interface and the free film surface often differ significantly from the bulk part of the film due to interface segregation or mixing and surface relaxation. For some thin film materials, phase transitions could occur as the film grows thicker and thicker. Therefore, it is necessary to be able to characterize the films at different depths. Grazing-incidence X-ray diffraction offers just such a technique, allowing convenient depth profiling in a non-destructive manner.

The grazing-incidence diffraction technique relies on both the capability of precise control of the X-ray incident angle and the capability of precisely aligning the sample surface. The SmartLab multipurpose diffractometer with Rigaku's patented cross-beam optics (CBO) offers a parallel beam solution to the first requirement and a completely automated sample alignment package for the second requirement.

Investigation

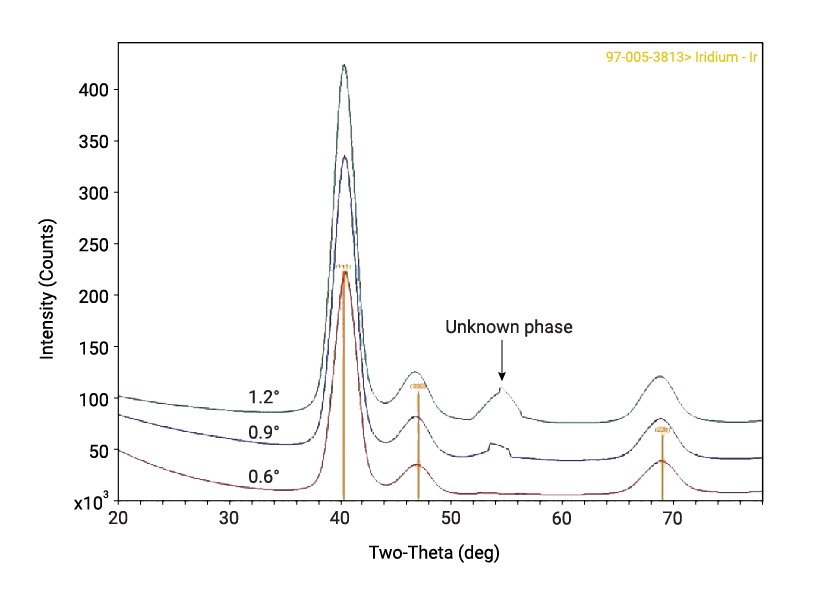

Figure 1 shows the grazing-incidence X-ray diffraction patterns of a 500 nm iridium thin film deposited on a Si substrate at varying incident angles. At a low incident angle of 0.6°, which is close to the critical angle for total external reflection of Iridium, the X-ray penetrates just a few nanometers deep into the film. Thus this diffraction pattern reflects the structure of the surface layer only, which appears to be perfect cubic iridium.