Application Note B-TA1031

Introduction

Thermomechanical analysis (TMA) is a method in thermal analysis that measures the change in length caused by expansion or shrinkage of a material as a function of temperature or time. In TMA, the measurement mode or attachment depends on the sample shape and measurement objective. The tensile loading attachment is suitable for materials such as fiber, sheet and films for the measurement of expansion and shrinkage. Here, the sample is clamped or fixed on both ends and the load is applied in the tensile direction. In this application, we apply the tensile loading method on the measurement of expansion of a thin aluminum sheet.

Measurements and results

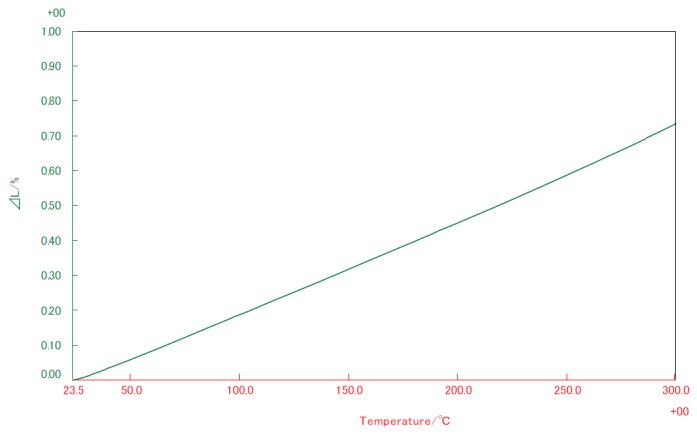

A high-purity Al sheet with a sample thickness of 10 μm and a length of 15 mm was used in this experiment. It was measured from RT~301℃ heating at 2℃ /min and applied with a constant load of 50 mN. The measurement result is shown in Figure 1.

Figure 1: TMA measurement result of 10μm Al sheet by tensile method

Result shows an increase in TMA signal indicating expansion in a linear manner ranging from 0.048%~0.723%. Calculated CTE values with a base temperature of 30℃ are tabulated in Table 1 which are compared to the literature values in a temperature basis. CTE values of the measured 10 μm Al sheet range from 2.40(x10⁻⁵) ~2.68(x10⁻⁵) K⁻¹ in which a good agreement can be confirmed between the obtained CTE values to the literature values. Note that the distance between the sample and the thermocouple is small, but it may affect the slight difference between the measured CTE values to the literature value.

Table 1: CTE values of 10 μm Al sheet with base temperature of 30℃

| Temp °C |

CTE Literature value (x10⁻⁵) K⁻¹ |

CTE 2°C/min (x10⁻⁵) K⁻¹ |

Expansion % |

| 50 | 2.375 | 2.40 | 0.048 |

| 100 | 2.400 | 2.53 | 0.177 |

| 150 | 2.429 | 2.56 | 0.307 |

| 200 | 2.463 | 2.59 | 0.440 |

| 250 | 2.500 | 2.62 | 0.577 |

| 300 | 2.541 | 2.68 | 0.723 |

Reference

Touloukian, Y. S.; Kirby, R. K.; Taylor, R. E.; Desai, P. D. Thermophysical properties of matter – The TPRC Data Series. Thermal Expansion on Metallic Elements and Alloys, vol12, 1975.