Application Note WDXRF1094

Introduction

The volume of seaborne trade and the price of iron ore have been globally increasing in recent years. For the iron ore industry, highly accurate analysis of total iron content in iron ore is a focal point.

In mining sites, it is often necessary to perform high volumes of analyses, as many as a few hundred samples per day. However, wet chemical analysis, the traditional analytical technique for total iron determination, is difficult to perform this scale because the method is time-consuming and requires significant analytical skill. The industry has a need for an analytical method that is fast, cost-effective, simple and accurate.

For the X-ray fluorescence analysis of powder samples, the pressed powder method is the best option in terms of quickness and simplicity. Since iron ore has a complex matrix owing to its various mineral assemblages, appropriate corrections for the matrix effect are required in XRF analysis. The conventional correction technique for total iron is a method using the Compton scattering as an internal standard (Compton scattering ratio method) but it has not been satisfactory for the requirements of the iron ore industry. Rigaku has developed an improved Compton scattering method by integrating a theoretical alpha correction so that the analytical results are significantly improved.

This note demonstrates the improved method determine total iron in iron ores by pressed powder method, which covers crude iron ores (low and high content iron ores) and agglomerates (pellet and sinter).

Instrument

The Simultix 15 is a simultaneous wavelength dispersive X-ray fluorescence (WDXRF) spectrometer with multiple-channels, which makes it capable of high-throughput analysis. The instrument is designed to provide reliable production control and stability for routine applications.

The Simultix 15 is equipped with a 4 kW X-ray tube and fixed channels optimized for the elements to be measured. Up to 40 fixed channels are available (optional) for simultaneous analysis. High-performance scanning goniometer channels (optional) are also available in place of some fixed channels. An intelligent Automatic Sample Changer (ASC), capable of placing up to 48 samples, is optionally available for high-demand jobs.

The tube-above optics of the Simultix 15 minimizes contamination from sample breakage during powder sample measurements. This configuration allows the use of pellets without adding any binding agents or analyzing smaller amounts than usual. It simplifies sample preparation and is cost-effective by reducing binding agent usage. A powder trap attachment avoids trouble in the vacuum system caused by scattering to grains from powder samples.

The operation software is improved in regard to daily-use operation. The newly integrated “Flowbar” in quantitative analysis guides users through calibration settings.

”Quant Scatter FP” is a unique optional function integrated with Rigaku FP system. It can be used to obtain theoretical alphas for the Compton scattering method applied to heavy element analysis in ore analysis. The ”Quant Scatter FP” function is available on the Simultix 15 system.

Standards and sample preparation

The standard samples used for calibration were 26 commercially available certified reference materials (CRMs). These standards are composed of hematite ore, magnetite ore, limonite, sintered ore, pellet and pure iron oxide. The range of total iron concentration in these CRMs is wide, from 19.6 mass% to 71.1 mass%, and the silica content ranges from 0.5 mass% to 53.7 mass%.

The well-dried (for 2 hours at 105˚C) samples were ground with a tungsten carbide container and then pressed at 250 kN using sample cups. In general, binders affect analysis results in the Compton scattering ratio method, therefore, it is strongly advisable to press samples without binder when the Compton scattering ratio method is applied.

Measurement and calibration

The Simultix 15 with a 4 kW Rh target X-ray tube was used to measure Fe, Si, Al, P, Mg, S, Ca, K, Ti, Mn and V element lines, and the Rh-Kα Compton scattering line. For the Fe-Kα measurement, an attenuator was used to obtain appropriate intensity without changing tube loading. The counting time was 40 s.

The calibration equation for “total iron” is as follows:

$W_{Fe} = (AI_R^2+BI_R+C)\cdot(1+\sum{a_jW_j})$

$I_R = I_{Fe}/I_{Compton}$

$a_j$: theoretical alpha of element j

$W_j$: weight fraction of element j

$I_{Fe}$: intensity of Fe-Kα line

$I_{Compton}$: intensity of Rh-Kα Compton line

$A, B, C$: constants

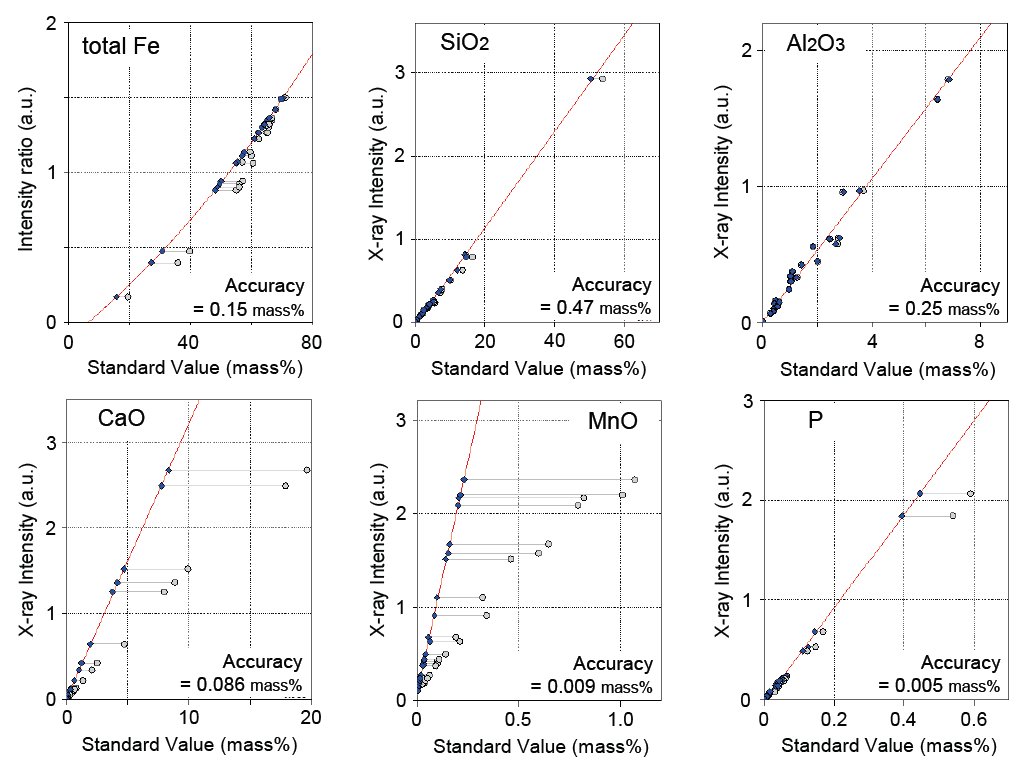

Figure 1: Calibration curves of representative components in iron ores. For the calibration curve of total iron, the Compton scattering ratio with theoretical alpha correction is used.

Calibrations for other components use the following equation:

$W_i = (BI_i+C)\cdot(1+\sum{a_jW_j})$

$a_j$: theoretical alpha of element j

$W_j$: weight fraction of element j

$I_{i}$: intensity of element i

$B, C$: constants

Matrix correction coefficients (alpha) applied to the matrix correction in the calibrations were theoretically calculated by the built-in program using FP. The theoretical alphas for total iron calibration were calculated taking into consideration the Compton scattering ratio by the Quant Scattering FP function integrated with the FP program.

Results

Calibration curves for typical components, including total Fe, SiO₂, Al₂O₃, MnO, CaO and P are shown in Figure 1. The accuracy of the total iron calibration is excellent, as shown in Figure 1.

Calibration accuracies for all components measured in this study are listed in Table 1.

Table 1: Accuracy of the calibration curves (unit : mass%)

| Component / Element | Concentration range | Typical accuracy of calibration |

| Total Fe | 19.57 - 71.09 | 0.15 |

| SiO₂ | 0.47 - 53.72 | 0.47 |

| CaO | 0.016 - 19.6 | 0.086 |

| MnO | 0.023 - 1.07 | 0.009 |

| Al₂O₃ | 0.27 - 6.81 | 0.25 |

| TiO₂ | 0.029 - 7.77 | 0.012 |

| MgO | 0.013 - 3.45 | 0.085 |

| P | 0.008 - 0.59 | 0.005 |

| S | 0.002 - 0.845 | 0.012 |

| K₂O | 0.003 - 0.676 | 0.007 |

| V | 0.001 - 0.46 | 0.005 |

Accuracy is calculated by the following formula:

$Accuracy = \sqrt{ \frac{\sum_i{(C_i-\hat{C}_i)^2}}{n-m} }$

$C_i$: calculated value of standard sample

$\hat{C}_i$: reference value of standard sample

n : number of standard samples.

m: degree of freedom (linear 2, quad. 3)

Conclusions

X-ray fluorescence spectrometry is a rapid, precise and accurate analysis method to meet the requirements of the iron ore industry. It can also minimize cost and time in iron ore analysis. A multi-channel system is best-suited for mine site or plant laboratories, where a high volume of sample analysis is required for quality and process control.

This application note demonstrates that the Quant Scatter FP method, which is the combination of the Compton scattering ratio method and the theoretical alpha correction, is practically applicable for analysis of various iron oxides and also a wide concentration range of samples, which indicates that the application is also available for laboratory analysis of brownfields and mine-site exploration as well as of production control.

The pressed powder method with Rigaku’s advanced correction technology is widely applicable to iron ore industries, such as suppliers, producers and steel manufacturers with higher cost-efficiency and higher throughput than conventional method.

Rigaku Simultix 15 has all the features stated above and is the best system for production and quality control of iron ore products.