Application Note B-XRD1121

Introduction

Crystal phase identification by XRD is used for R&D and QC in a wide range of industries, including ceramics, metals, and pharmaceuticals. In the conventional method of crystal phase identification, the software for data measurement and analysis was separate. For this reason, the additional step of loading the data into the analysis software was required, and some system even required data pre-processing, such as smoothing and background removal. These operations were complicated and time consuming. The "Real-time analysis" function found in the integrated X-ray analysis program “SmartLab Studio II” automatically searches for crystal phase candidates during measurement and displays the results of phase identification and the quantitative values in real time. In this application, real-time analysis was performed on a mixed powder sample of corundum (α-Al₂O₃), rutile (TiO₂), and anatase (TiO₂).

Measurements and results

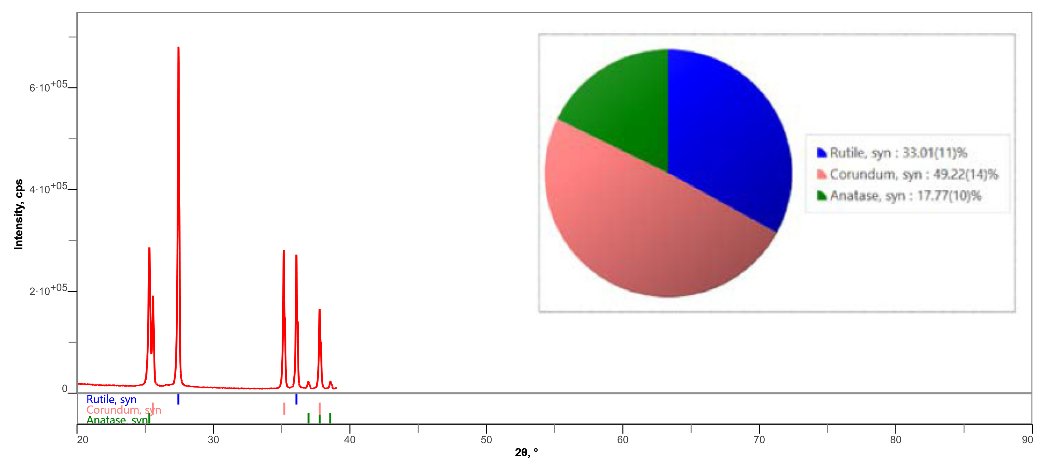

Phase identification was automatically carried out each time a new diffraction peak was observed during the measurement, and crystal phase candidates were displayed. When multiple crystal phases were identified, quantitative analysis was performed to calculate the weight ratio of each crystal phase. Figure 1 shows the result of the real-time analysis in the measurement range up to around 2θ = 40˚. Since analysis results can be checked during the measurement, it is possible to judge whether the measurement should be continued or canceled. As shown in Table 1, the quantitative values obtained at the end of the measurement were in good agreement with the prepared values.

Figure 1: Real-time analysis result of mixed powder at around 2θ=40˚.

Table 1: Quantitative analysis of the mixed powder by the RIR method.

| Crystal phase | mass % | |

| Analysis value | Preparation value | |

| Corundum (α-Al₂O₃) | 54.15(18) | 52.91 |

| Rutile (TiO₂) | 33.71(18) | 34.22 |

| Anatase (TiO₂) | 13.15(8) | 12.88 |