Application Note EDXRF1331

Scope

This application note demonstrates the analysis of sulfur and chlorine in crude oil using NEX QC+.

Background

Monitoring the sulfur and chlorine content is important in various oils and oil products. In crude oil, chlorine may be present through natural processes or possible adulteration. If unmeasured or not corrected for, chlorine may bias the sulfur measurement or potentially cause damage in the refining process. The industry requires a fast, simple means of screening and monitoring the chlorine content of crude at the well site, along pipelines, during blending and other pre-refining checks. In these cases and others, Applied Rigaku Technologies meets the challenge of monitoring and measuring the sulfur and chlorine content of oils with the use of compact benchtop instrumentation that use semiconductor detectors. These systems can easily resolve and measure the sulfur and chlorine, as well as vanadium and nickel present in the oil. See also App Note #1323.

Calibration

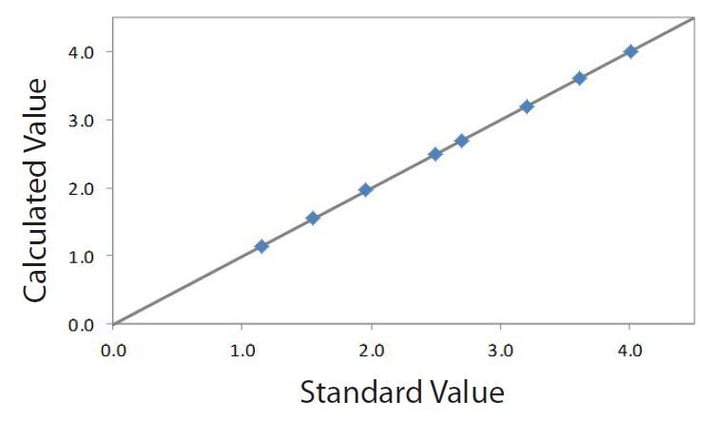

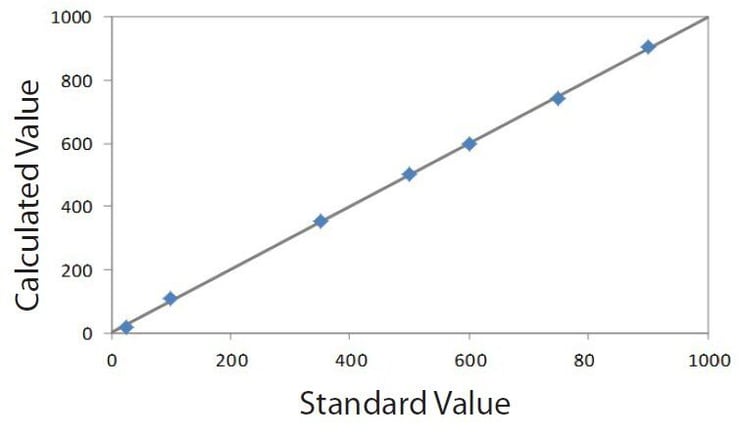

Eight commercially available certified crude oil standards were used to develop empirical calibrations for S and Cl. The results shown here demonstrate measuring crude oil containing sulfur levels between 1 – 4% and chlorine between 25 – 1000 ppm.

| Element: S Units: % |

||

| Sample I.D. | Standard value | Calculated value |

| STD 3 | 1.152 | 1.147 |

| STD 4 | 1.554 | 1.553 |

| STD 5 | 1.952 | 1.961 |

| STD 6 | 2.501 | 2.504 |

| STD 7 | 2.701 | 2.702 |

| STD 8 | 3.202 | 3.192 |

| STD 9 | 3.607 | 3.607 |

| STD 10 | 4.003 | 4.007 |

Correlation plot S

Correlation plot S

| Element: Cl Units: ppm |

||

| Sample I.D. | Standard value | Calculated value |

| STD 3 | 901 | 905 |

| STD 4 | 25 | 17 |

| STD 5 | 750 | 741 |

| STD 6 | 100 | 109 |

| STD 7 | 600 | 599 |

| STD 8 | 1001 | 1002 |

| STD 9 | 350 | 354 |

| STD 10 | 500 | 501 |

Correlation plot Cl

Correlation plot Cl

Repeatability

To demonstrate repeatability (precision), two typical calibration standards were selected. Each was measured in 10 repeat analyses without moving the sample between measurements.

| Sample: Std 4 | ||||

| Element | Standard value | Average value | Std. dev | % Relative dev |

| S (%) | 1.554 | 1.572 | 0.006 | 0.4 |

| Cl (ppm) | 25 | 21 | 2 | 8 |

| Sample: Std 8 | ||||

| Element | Standard value | Average value | Std. dev | % Relative dev |

| S (%) | 3.202 | 3.187 | 0.014 | 0.4 |

| Cl (ppm) | 1001 | 995 | 3 | 0.3 |

Conclusion

The NEX QC+ offers analysts and technicians a simple yet powerful and versatile system for quantifying elemental composition using the empirical approach. The results of this study indicate that given stable samples, proper sample handling and proper calibration technique, the Rigaku NEX QC+ EDXRF can achieve excellent results in screening and monitoring the concentration of sulfur, chlorine and other elements in crude oil and other similar oils.