Application Note EDXRF1994

Scope

Demonstrate Material Identification for standard ASTM and JIS alloy tables and user-definable custom identification tables.

Background

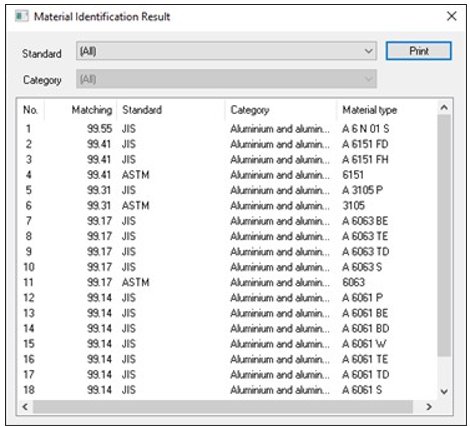

Material identification, also called positive material identification or PMI, is used to analyze and identify materials for quality assurance and quality control to verify proper alloy or material is being used. Material identification can also be used to quickly sort unknown alloys and other materials, including powders and liquids, and can be used in industrial forensics and failure material analysis identification. By looking at the structure of the elemental constituents in a sample, material identification verifies material type by comparing differences in composition that define the specific types of materials being analyzed.

XRF offers a non-destructive means for material identification. Applied Rigaku Technologies EDXRF systems offer the standard alloy identification tables as well as the capability for the user to create a custom table defined for any material where the types of materials can be differentiated by differences in element composition.

Standard alloy identification tables

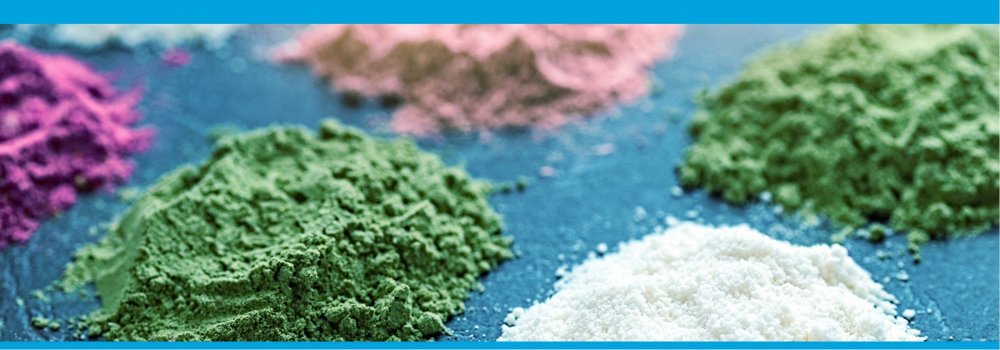

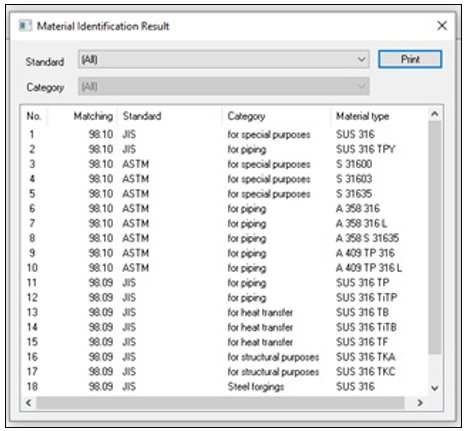

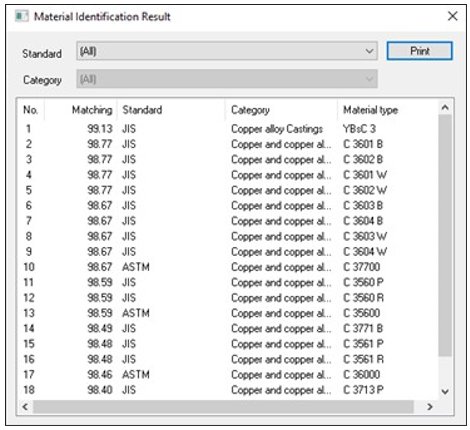

The ASTM and JIS standard alloy tables for ferrous, aluminum, and copper alloys are included.

In this example, an unknown piece of stainless steel is measured using semi-quant FP and identified as SS316.

Identification of unknown brass sample

Identification of unknown aluminum sample

Custom identification table

Rigaku Material Identification software allows the user to create and define a custom identification table for any material where the types of the material are differentiated by elemental composition.

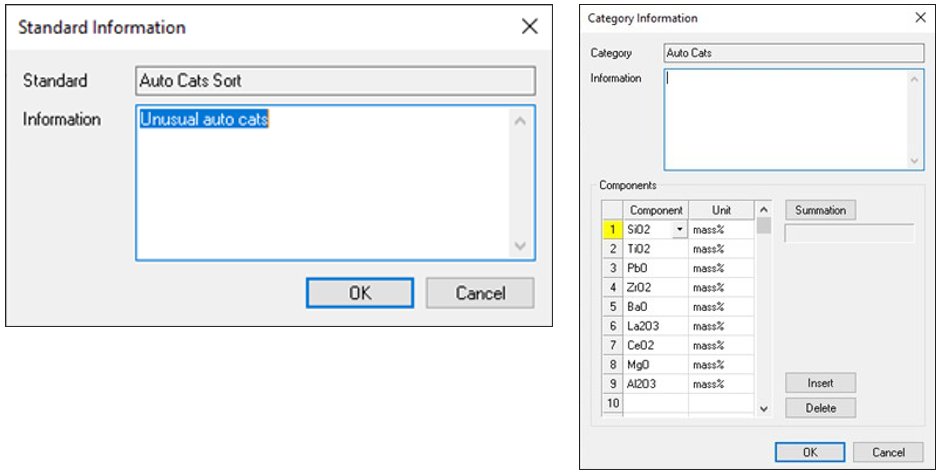

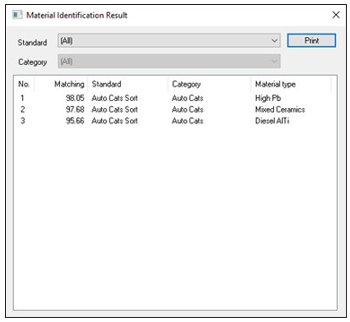

In this example, an identification for sorting unusual auto cats is demonstrated. The material types and criteria for differentiating are determined by the user to best fit the specific needs at the facility.

Create a new standard table, define the category, and list the major elements in the material that are used to differentiate the various material types.

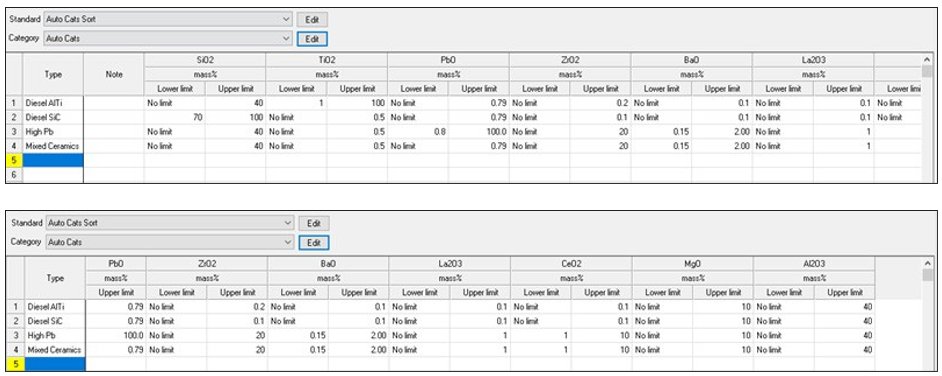

Next, list the types of material and enter the elemental limits that define the differences between each type.

Next, list the types of material and enter the elemental limits that define the differences between each type.

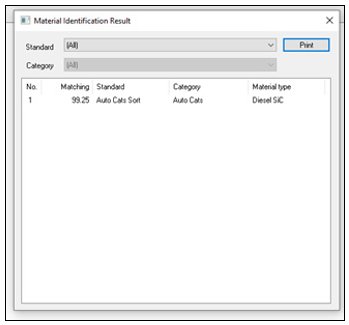

Example of identification of SiC diesel auto cat sample

Example of identification of SiC diesel auto cat sample

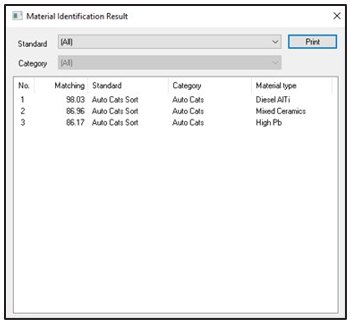

Identification of an aluminum titanate diesel cat.

Identification of an auto cat with unusually high lead

Identification of an auto cat with unusually high lead

Conclusion

Rigaku Material Identification software gives the user a tool for alloy PMI and the ability to create custom identification tables for material verification and sorting applications.