Analyze raw materials to finished cement

Modern Portland cement is made by mixing substances containing lime, silica, alumina, and iron oxide and then heating the mixture until it almost fuses. During the heating process dicalcium and tricalcium silicate, tricalcium aluminate, and a solid solution containing iron are formed. X-ray fluorescence (XRF), a standard technique across the cement industry, is used to determine metal-oxide concentrations and oxide stoichiometry. X-ray diffraction (XRD) provides quantitative analysis of free lime in clinker, which is critical to the production process. Kiln parameters are monitored, and adjusted continuously, based on XRD and XRF analytical results. Rigaku technology and know-how provide a number of unique solutions for these measurements.

Application Notes

The following application notes are relevant to this industryXRD

EDXRF

WDXRF

WDXRF, XRF

Rigaku recommends the following systems:

XRD

New 6th-generation general purpose benchtop XRD system for phase i.d and phase quantification

High-performance, multi-purpose XRD system for applications ranging from R&D to quality control

X-ray CT

WDXRF

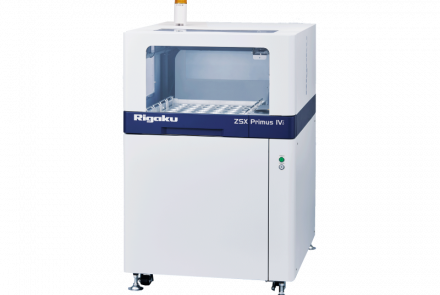

High-power, tube-below, sequential WDXRF spectrometer with new ZSX Guidance expert system software