Application Note B-TA2039

Introduction

Plastics made from plant-derived (biomass), so-called “biomass plastics”, have almost the same composition and physical properties as petroleum-derived plastics, and biomass-derived resins containing a certain percentage of biomass are used as products. It is also generally believed that biomass plastics and petroleum-derived products can be distinguished only by the abundance of C14, which is the isotope of C13. In this study, biomass plastic made of polyethylene used in shopping bags on the market and high-density polyethylene used as a reagent that does not contain biomass were compared and measured by TG-FTIR and evaluated.

Measurement and results

High-density polyethylene (HDPE) regent and three types of commercially available plastic bags (25%, 30%, 50%) with different biomass ratios, approximately 5 mg, were used. Inert nitrogen gas (N₂) and oxidizing (air) gas with a mass flow meter set to a flow rate of 200 mL/min were used as atmospheric gases during the measurement. The holding temperature of the TGA-IR module was set to 300°C to prevent condensation in the introduction path of evolved gas.

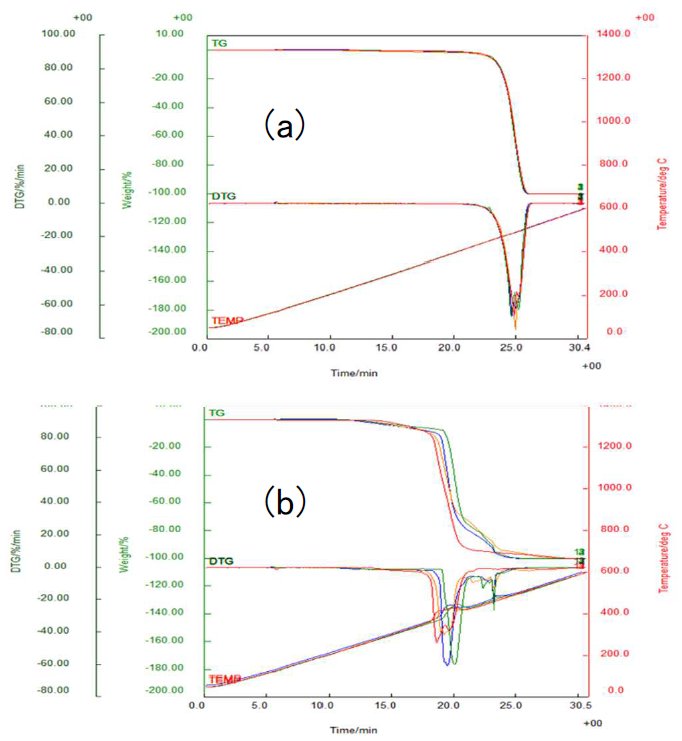

Figure 1 shows a comparison of TG (DTG) curves in N₂ gas and air gas atmospheres for three commercial plastic bags with different biomass ratios (25%, 30%, 50%) and HDPE. The mass loss in N₂ gas flow and the thermal decompositon behavior from the evolved gas (IR spectrum) by TG-FTIR were exactly the same, making it difficult to distinguish between HDPE and the biomass plastics.

On the other hand, a comparison of the same samples in air atmosphere reveals that all samples start with primary oxidative decomposition at around 220°C. After proceeding through a certain decomposition process, following a second-stage rapid mass loss due to the combustion at around 360-450℃, the biomass-mixed samples further caused a third-stage intense oxidative combustion at around 500℃. A clear difference can also be observed in the thermal decomposition behavior between HDPE and the biomass plastics. With increasing the biomass ratio, the thermal decompositions in the second stage gradually shifted to higher temperatures, and the difference in the biomass ratios were revealed.

Figure 1: Comparison of TG (TG derivative: DTG) obtained from nitrogen atmosphere (a) and air atmosphere (b) for three types of plastic bags with different biomass ratios (25%, 30%, 50%) and HDPE

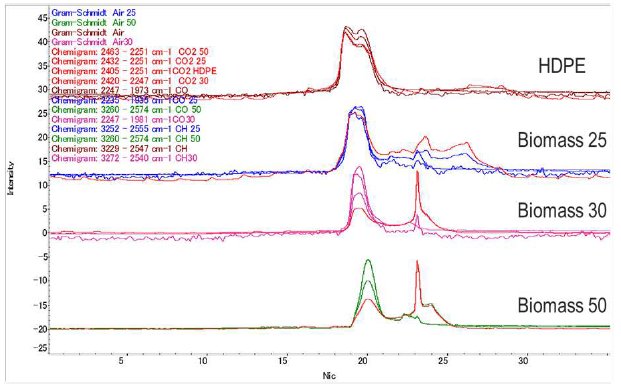

Figure 2: Comparison of Gram-Schmidt curves and chemigram curves for CO, CO₂, and hydrocarbons obtained in air atmosphere for three plastic bags with different biomass ratios (25%, 30%, 50%) and HDPE