Elemental, phase and residual stress analysis

Quality production demands control of material properties throughout the entire process from raw material to finished product. The speed and precision of X-ray fluorescence (XRF) elemental analysis make it a preferred testing method in high sample throughput chemical analysis. In addition to alloy stoichiometry, X-ray diffraction (XRD) examines phase composition, retained austenite concentration or residual stress, which correlate with structural quality of your products.

Application Notes

The following application notes are relevant to this industryXRD

WDXRF

EDXRF

X-ray Imaging

Thermal Analysis

XRD, Stress

Process

Rigaku recommends the following systems:

WDXRF

Benchtop tube below sequential WDXRF spectrometer analyzes O through U in solids, liquids and powders

High-throughput tube-above multi-channel simultaneous WDXRF spectrometer analyzes Be through U

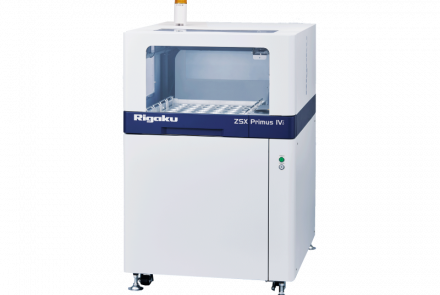

High-power, tube-below, sequential WDXRF spectrometer with new ZSX Guidance expert system software