Background

A Cu thin film is used in various devices and its crystal structure, texture and other properties need to be understood well to improve performance of those devices. Those devices often go through high temperature treatments during production process and it is important to understand how its structure is affected by temperature change. X-ray diffraction is one of the analysis techniques used to study Cu structure and the analysis can be done in a high temperature environment.

Investigation

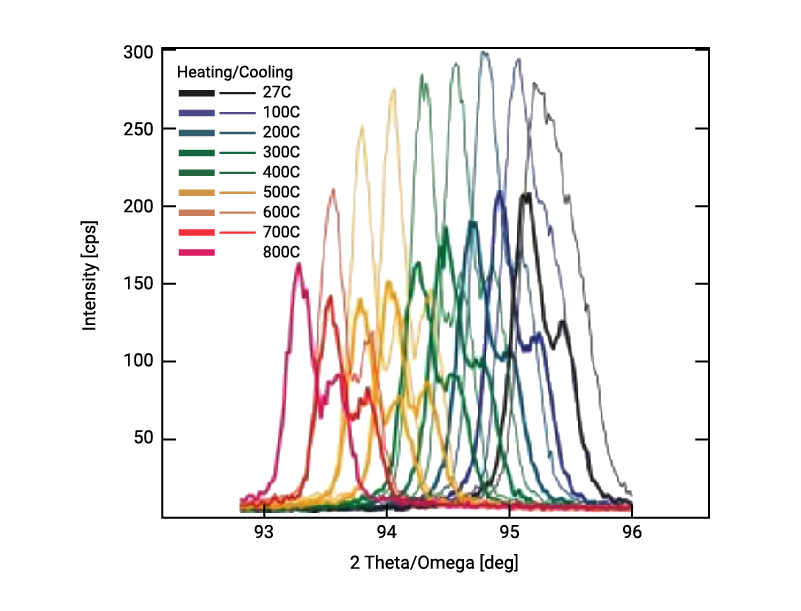

Figure 1 shows grazing incidence in-plane (Cu (220)) and conventional out-of-plane (Cu (222)) diffraction data collected on a 197 nm thick Cu film on Si substrate. The sample temperature varied from 27 to 800°C in nitrogen and peak position and width change were observed as the sample temperature changed. The data was collected on the SmartLab diffractometer with the Anton Paar DHS1100 hot stage.

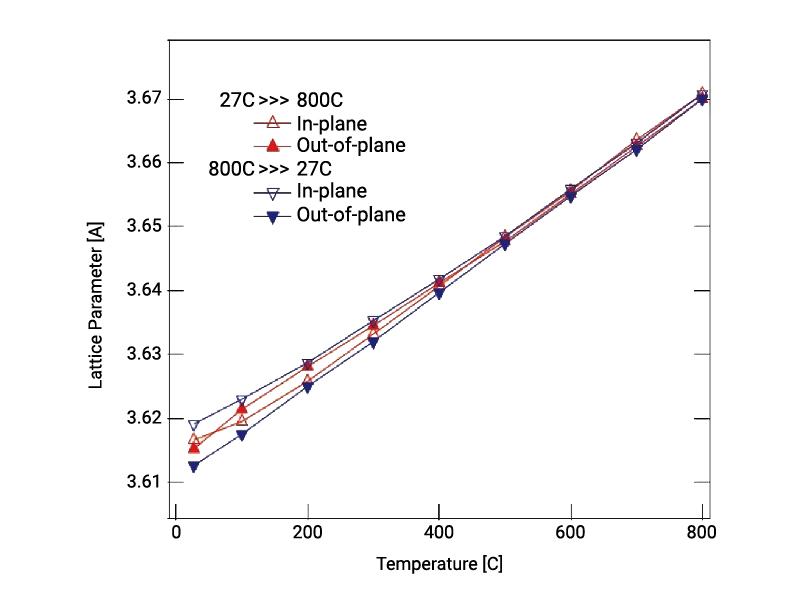

The lattice parameters and FWHM at different temperatures were calculated from those scans (Figures 2 and 3).

|

|

The lattice parameter analysis results indicate that the Cu lattice was strained at room temperature. As the sample was heated, the Cu lattice expanded vertically first then relaxed around 400°C. The lattice continued to expand up to 800°C. As the temperature decreased, the lattice started to become strained again because the thermal coefficient parameter of Si is smaller than that of Cu. At room temperature, the lattice became more strained than it was before the heating experiment. The FWHM analysis results indicate that the crystal quality of the Cu layer improved as the temperature increased but it deteriorated as the temperature decreased. At room temperature, the ordering in the out-of-plane direction became less than before the heating experiment.