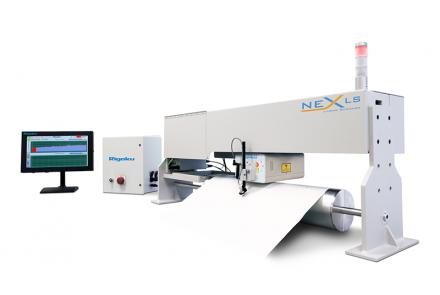

X-ray analytical information, such as elemental analysis, chemical composition, or molecular structure data, is commonly used to provide critical data to the statistical process control (SPC) model controlling a process. Rigaku makes a variety of real-time process analyzers. The NEX XT is an advanced X-ray transmission / absorption total sulfur gauge for crude oil, marine bunker fuel and blending operations. NEX OL represents the next evolution of process EDXRF elemental analysis for liquid stream and fixed position web or coil applications. The NEX LS delivers scanning multi-element process coatings analysis, of elements from Al to U, by EDXRF spectroscopy; this coil/web analyzer provides cross web and down web profiling of coating weight thickness and elemental composition.

For at-line process or quality control, Rigaku offers a variety of robust X-ray instruments designed for the production environment. X-ray Diffraction (XRD) is used for the determination of crystallinity or polymorph validation in pharmaceuticals or minerals, for example. X-ray Fluorescence (XRF) can control many disparate production processes, from the stoichiometry of metal oxides in cement production to critical additives in plastics or metal alloys and sulfur in fuels or any other PC or QC application for X-rays. Rigaku Instruments, expertise and services ensure your process control.